SOCOTEC offers advanced petrographic analysis to diagnose material performance, durability risks, and root causes in concrete, aggregates, rock, and other construction materials across the United States.

Enhancing Material Performance with Petrographic Analysis

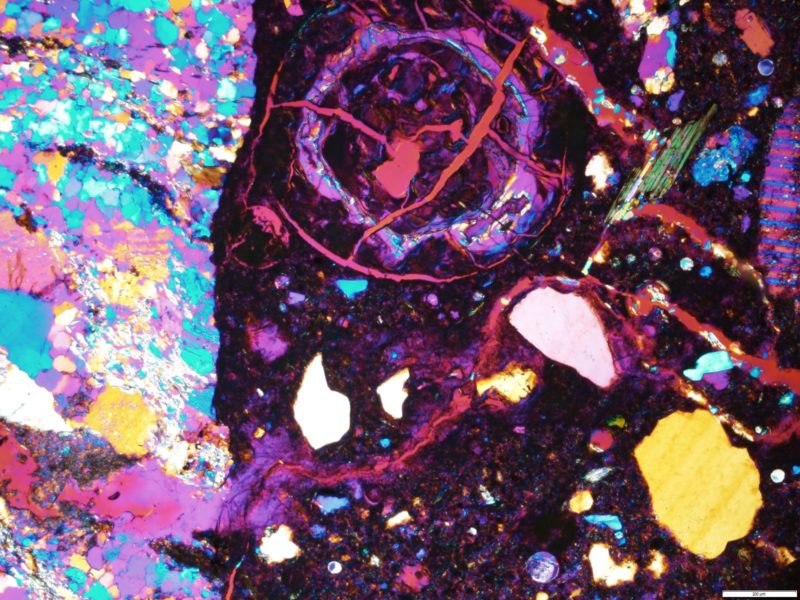

When built assets deteriorate unexpectedly, understanding the root cause is essential to preventing costly failures and ensuring long-term durability. Petrographic analysis provides the microscopic insights needed to identify material defects, reactions, and structural vulnerabilities that threaten your project's integrity.

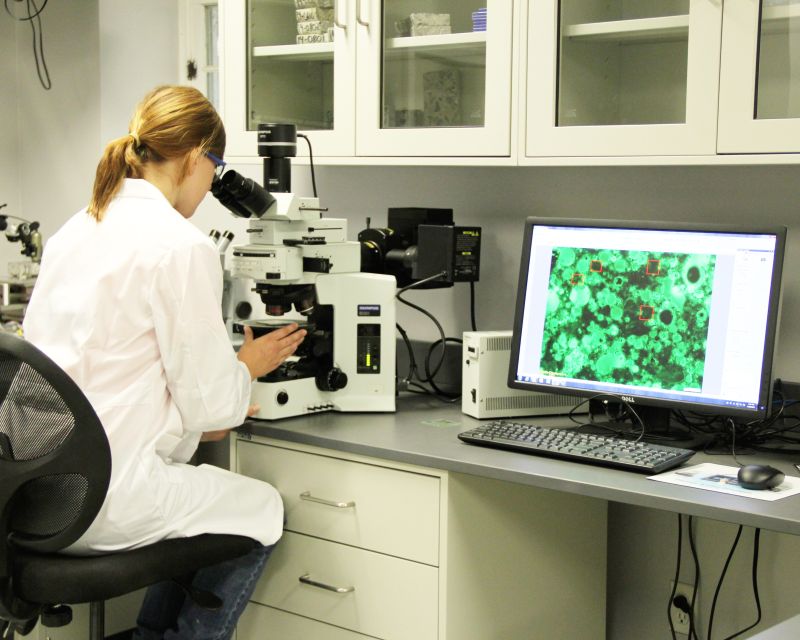

At SOCOTEC, our state-of-the-art petrographic laboratory combines advanced microscopy, rigorous ASTM petrographic analysis procedures, and experienced petrographers to deliver actionable insights for owners, engineers, contractors, and public agencies in the US. We help clients understand what went wrong, why it happened, and how to move forward with confidence.

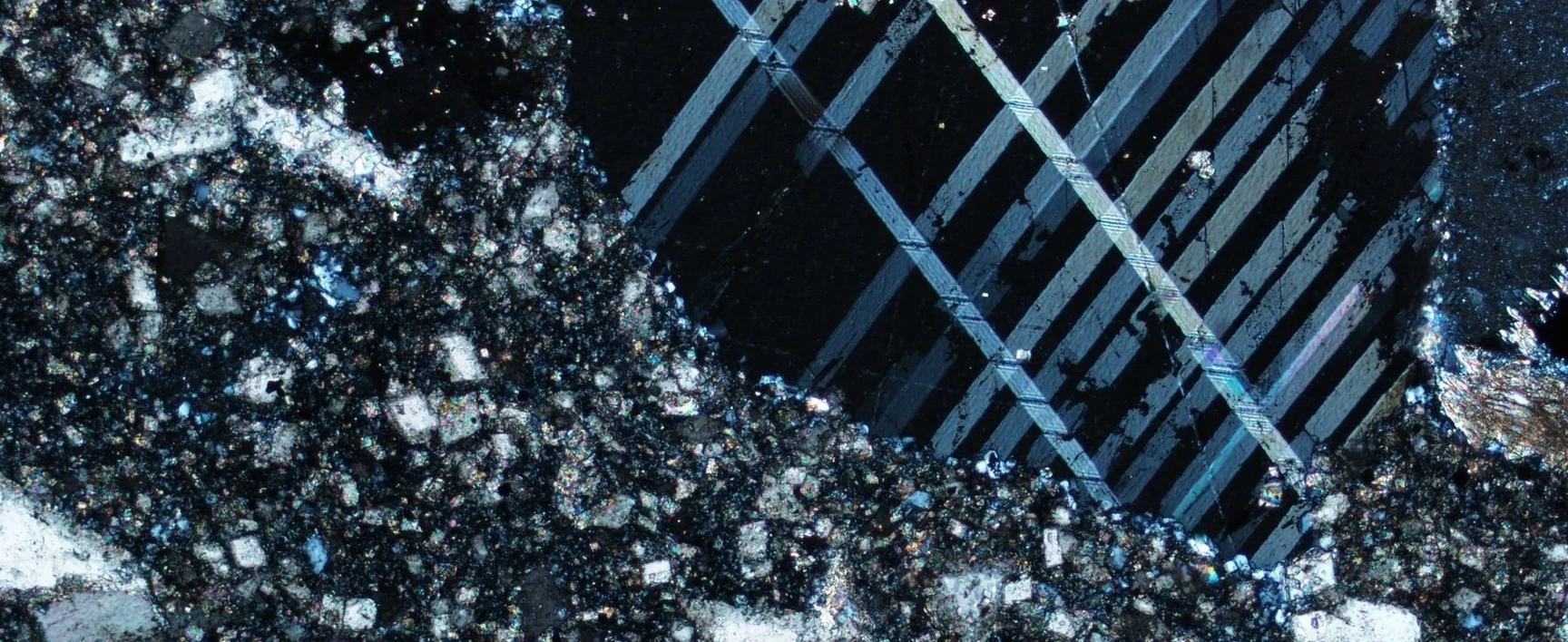

Our Petrographic Analysis Lab

Project Types and Industries

SOCOTEC conducts petrographic analysis for a wide range of projects and industries where material performance is critical:

- Transportation infrastructure: highway and bridges structures experiencing premature deterioration, pavement and concrete roadway assessment for DOT projects, parking structures with scaling, spalling, or cracking issues, transit assets

- Industrial and energy facilities: power generation facilities with concrete degradation, water treatment plants and industrial infrastructure, marine structures exposed to harsh environmental conditions

- Commercial, residential, and mixed-use buildings: building foundations and structural elements showing distress, facade and exterior masonry analysis for restoration projects

- Historic structures and preservation projects requiring petrographic analysis of mortar and stone

- Government and state agency programs

- Legal and insurance-driven forensic investigations: materials failure mechanisms and contributing factors, construction defect litigation support, quality control failures during construction, long-term durability assessments

When to Conduct Petrographic Analysis?

Petrographic analysis is a powerful tool for diagnosing materials issues. You should consider conducting petrographic analysis if the following situations occur.

Why Choose SOCOTEC for Petrographic Analysis

Advanced Petrographic Laboratory

SOCOTEC operates a state-of-the-art petrographic analysis lab with extensive thin-section libraries and advanced microscopy techniques.

Proven Forensic Expertise

Our petrographers support complex investigations, disputes, and forensic engineering cases with defensible, well-documented findings.

Practical, Actionable Reporting

Every petrographic analysis report is written to support real-world decisions, not just laboratory observations.

Trusted Regional and National Partner

From New England and Florida to nationwide projects, SOCOTEC delivers consistent quality, responsiveness, and trusted expertise.

Ready to Solve Your Material Performance Project?

Don't let material failures compromise your project.