When SOCOTEC’s Specialty Engineering group was founded in 1885 by Dr. Lucius Pitkin, its mission was to provide chemical consulting to local industries. One hundred forty years later, we continue the tradition as a leading consultant in materials. SOCOTEC provides a wide range of materials analysis and testing services for design, selection and specification as well as performance, aging and failures. We dedicate the use of novel alternate materials for applications through analysis and testing. We provide training in all aspects of materials engineering.

SOCOTEC has worked with many industries on improved material design in response to failures and unanticipated loads or conditions. We have particular expertise in materials condition assessment—crucial in a time of aging infrastructure. Our work with the Electric Power Research Institute has addressed material issues in transmission and distribution, equipment and subcomponents, material degradation mechanism such as FAC and MIC, and material property degradation due to radiation.

Materials & Failure Analysis

In many instances, improved structural or equipment performance is obtained by material enhancements. SOCOTEC’s comprehensive engineering experience provides the basis for addressing today’s most complex materials problems. Such experience is most vital in the joining of materials—i.e., welding and bolting—and the fabrication of connections, where most failures occur.

Accurate fracture and failure analysis also require extensive experience and technical capabilities. Understanding the mechanisms and root cause of a failure generally solves not only short term operational problems, but if properly performed can lead to structural or equipment performance improvements.

Talk to our experts

Laboratory Services

Materials Testing and Evaluation

SOCOTEC maintains a pair of laboratory facilities to support our failure analysis and materials testing efforts. The main Materials Testing and Analysis Laboratory in Brooklyn boasts state of the art equipment for materials characterization, testing, performance simulations and analysis. Its capabilities include:

- Materials testing and analysis: metals, concrete, asphalts, polymers, composites, coatings, adhesives, lubricants

- Material selection and characterization

- Fracture mechanics

- Hardness and Microhardness testing

- MICS

- Fatigue

- SEM and EDS

- Metallurgical tests

- Visual inspections, optical microscopy, scanning electron microscopy

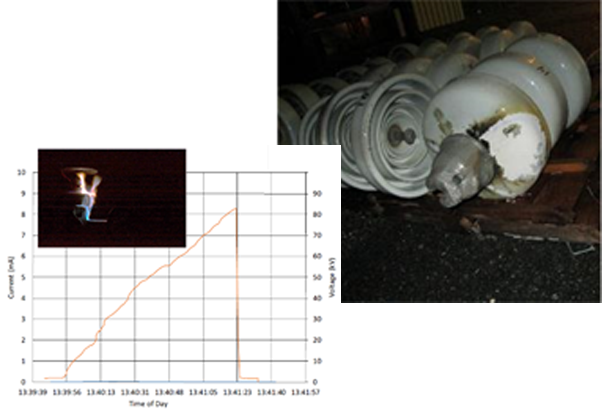

- Electrical component operation simulations

- Mechanical simulations

- Chemical analysis

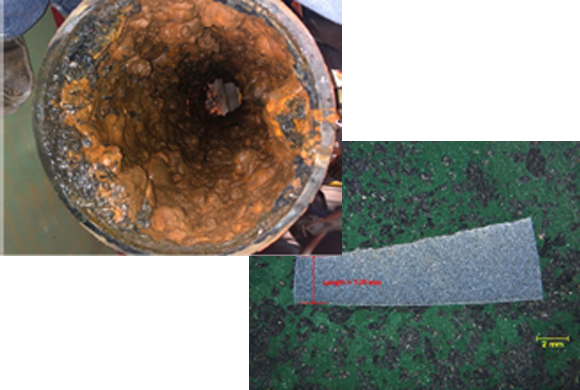

- Aging and materials degradation: corrosion, erosion, wear, fracture, fatigue, creep, thermal and microbiological effects

- Environmental effects: accelerated corrosion, salt spray, and adverse chemical exposure

- Loading tests: static and dynamic, vibration, hydraulics, impact, explosion

Component and System Evaluation

Tests and simulation mock-ups are used to solve engineering problems or to assess material, component, or system integration performance. SOCOTEC can conduct full-scale simulations and tests in our Brooklyn lab. This facility hosts environmental studies for building facades, fluid flow simulations including waterhammers, and other tests requiring expanded testing volume.

- Structural Testing: strength testing, vibrations

- Mechanical Testing: rotating equipment, pressure vessels, valves

- Electrical Testing: conductors, insulators and insulations, jackets, motors, solenoids, transformers and fuses, analog and digital equipment)

SOCOTEC can receive low-level radioactive component samples through our Annex in Amesbury, Massachusetts. Samples can undergo direct analysis and testing, including SEM, EDS, fractography, microscopy, or strength testing. Alternatively, we can decontaminate and forward them to our main laboratory facilities.

Metallurgical, Materials and Corrosion Evaluations

Degraded plant components require appropriate informed evaluations to ensure continued operations, repair and replace decisions, and corrective action. SOCOTEC offers comprehensive metallurgical and materials evaluations, either directly in the field or in our comprehensive laboratory in New York. Our technical specializations include corrosion assessments, IGSCC determinations, corrosion fatigue, and creep evaluations. The SOCOTEC staff can provide insight in the material selection process of design and to assist maintenance organizations throughout the complete life cycle of components installed at plants.

Welding Engineering

SOCOTEC’s welding engineers and AWS-certified technicians have been involved in numerous welding-related investigations. In many cases, fabrication and/or assessment procedures have been devised to obtain structurally sound welded connections which otherwise might have been impractical. In addition, we provide welder and procedure qualification testing to the requirements of the American Welding Society, American Bureau of Shipping and ASME Boiler and Pressure Vessel codes. SOCOTEC is an AWS Accredited Test Facility.

Failure Analysis Training

SOCOTEC offers failure analysis-related training in our core areas that are designed for the plant engineer, technician, operations, or maintenance individual. The courses cover a wide range of subjects:

- Material and engineering fundamentals—material aging degradation, fracture mechanics and fatigue, corrosion, extreme loads

- Failure analysis tools and methods—FMEA, HAZOP and FTA, walkdowns and surveys, critical thinking skills for failure determination, instrumentation design and deployment

- Design for lifecycle—strategies for reducing premature structure or component failure by identifying and designing for failure mechanisms.

Want to know more about our Failure Analysis services?