How To Prevent Costly Failures Through Quality Assurance For Data Centers?

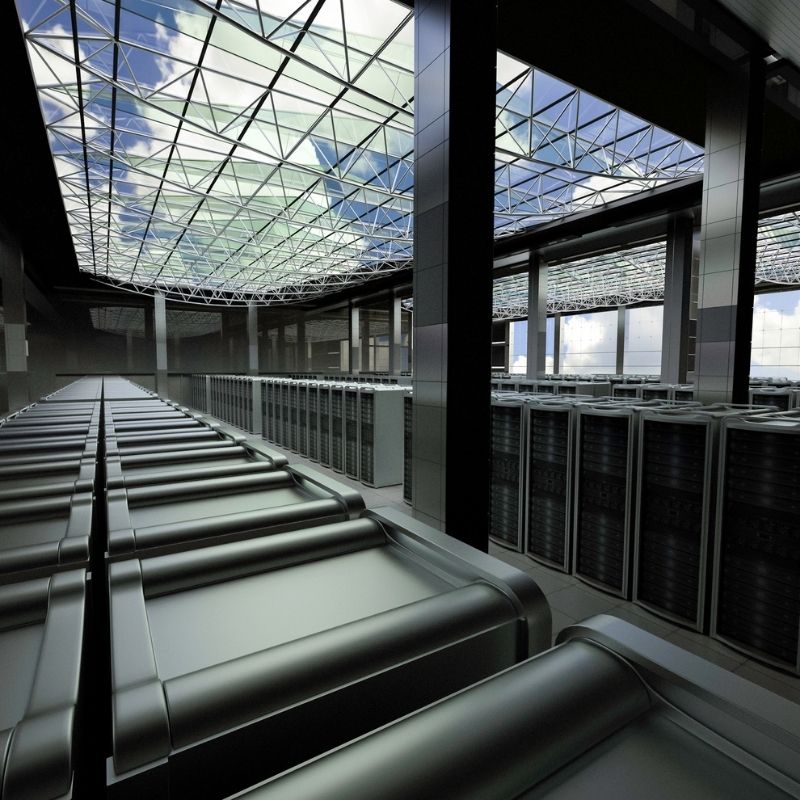

In the high-stakes world of data center construction, where mission-critical equipment worth millions of dollars requires absolute protection from environmental elements, building envelope performance is paramount. Data centers represent some of the most demanding building environments in modern construction and require absolute protection from weather elements, unable to tolerate envelope failures of any kind. Yet despite their critical nature, building envelope systems often receive less attention than the mechanical, electrical, and plumbing (MEP) components they're designed to protect.

The Critical Role of Building Envelope Performance

How can proper commissioning protocols salvage major data center projects from catastrophic roof failures? A recent case study from a large-scale data center provides valuable insights into how proper building envelope commissioning (BECx) can prevent costly failures and protect substantial investments. Building Envelope Commissioning (BECx) is not just recommended but essential for these mission-critical facilities often constructed under the most stringent time contraints. The project's experience offers valuable insights into how proper commissioning protocols can identify and prevent costly failures before they impact operations.

Understanding Building Envelope Commissioning

Building Envelope Commissioning is a systematic quality assurance process that ensures building envelope systems perform according to design intent and specified requirements throughout the entire project lifecycle. Unlike traditional quality control measures that focus primarily on material compliance, BECx provides comprehensive validation from design development through long-term performance verification.

Data centers represent unique construction challenges where the shell and core, though accounting for a relatively small percentage of total project costs, must provide uncompromising protection for expensive MEP systems and servers housed within. Further, the construction schedules are often “fast tracked” with limited time for installations to be accomplished, let alone reworked due to issues. There are no code required special inspections for the building envelope, like there are with structural connections. The building envelope demands the same level of attention as structural connections and critical mechanical and electrical systems, requiring comprehensive commissioning from design development through occupancy.

Let's Power Up!

Project Background and Design Intent

The project featured an innovative design with no roof penetrations on the main network and data hall buildings, specifically intended to minimize leak potential based on a history of roof leaks experienced in other building designs. The assembly included:

- Cement-based thermal barrier board mechanically attached to 18-gauge galvanized steel deck

- Torch-applied vapor barrier serving dual purpose as temporary roof coverage

- Two layers of 2.2" polyisocyanurate insulation in hot asphalt or adhesive

- Gypsum cover board installed in hot asphalt or adhesive

- PVC/KEE single ply membrane in hot asphalt or adhesive

The design incorporated stringent performance requirements, including FM Global 4450/4470 standards compliance, Class 1-90 windstorm rating with 2:1 safety margin, Class A fire rating, and minimum R-25 thermal value.

The project featured an innovative design with no roof penetrations on the main network and data hall buildings, specifically intended to minimize leak potential based on a history of roof leaks experienced in other building designs. The assembly included:

- Cement-based thermal barrier board mechanically attached to 18-gauge galvanized steel deck

- Torch-applied vapor barrier serving dual purpose as temporary roof coverage

- Two layers of 2.2" polyisocyanurate insulation in hot asphalt or adhesive

- Gypsum cover board installed in hot asphalt or adhesive

- PVC/KEE single ply membrane in hot asphalt or adhesive

The design incorporated stringent performance requirements, including FM Global 4450/4470 standards compliance, Class 1-90 windstorm rating with 2:1 safety margin, Class A fire rating, and minimum R-25 thermal value.

Pre-Construction Challenges in Fast-Track Environments

Data center construction typically follows aggressive "fast track" schedules where completion dates are established before final contract negotiations. This timeline pressure often compromises essential pre-construction activities including:

FM 1-52 Testing Reveals Widespread Roof Failures

Systematic uplift resistance testing following FM 1-52* protocols revealed critical roof failures across multiple buildings. Two primary failure modes were identified:

- Membrane Adhesion Failure: Inadequate bonding between roof membrane and underlying asphalt layer

- Coverboard Delamination: Poor adhesion between gypsum coverboard and asphalt layer on insulation

Investigation revealed that asphalt quantities in failed areas fell below specified minimums, though material testing confirmed all components met published specifications. The failures resulted from installation methodology rather than defective materials.

When initial membrane attachment failures occurred on the Administration building, shortly after roof installation was completed, testing expanded to the data hall building where installations were underway. Different failure patterns emerged, specifically coverboard release from underlying asphalt layers due to inadequate bonding during hot asphalt application.

A modified installation methodology was successfully tested, involving weighting coverboards with stored materials rather than relying solely on crew members walking boards into position. Despite successful validation testing, the installing contractor reverted to original methods, citing manufacturer installation guidelines.

This case demonstrates why comprehensive roofing forensics and building envelope expert consultation during the design and construction phases are essential for preventing costly failures in critical infrastructure projects.

*FM Global Property Loss Prevention Data Sheet 1- 52, Field Verification of Roof Wind Uplift Resistance.

Quality Control Integration Challenges The Project Revealed

Daily Reporting Deficiencies:

- Despite contractual requirements and established protocols, installing contractors failed to provide required daily QA/QC reports.

Observation Limitations:

- While daily third-party inspections were requested, sequencing and multiple crew operations prevented 100% installation coverage.

- Manufacturer inspections for warranty focus on “leak proof” performance and do not assess or confirm securement for wind resistance.

Communication Gaps:

- Roofing quality programs weren't integrated into submittal packages or shared with commissioning agents.

Remediation and Lessons Learned

Four repair options were developed ranging from wholesale membrane replacement to targeted repairs with perimeter reinforcement. Each option required manufacturer warranty validation and carried distinct schedule and risk implications.

The collaborative approach between the hyperscale owner's risk management team, general contractors, manufacturers, and commissioning agents resulted in comprehensive solution development, though implementation extended well into the construction timeline.

Best Practices for Future Data Center Projects

Design Phase Integration

- Include BECxA in all design coordination meetings, particularly 30% reviews

- Develop comprehensive materials matrices before design meetings

- Ensure specification currency and standard references

- Integrate building envelope requirements with MEP coordination

Pre-Construction Protocol Enhancement

- Complete submittal reviews before pre-installation meetings

- Conduct both Preliminary Roofing Conferences and Pre-Installation Meetings

- Implement meaningful mock-up installations with proper materials and scale

- Establish clear quality assurance reporting requirements

Construction Phase Optimization

- Enforce daily QA/QC reporting from all contractors

- Integrate commissioning agents with contractor quality programs

- Implement systematic performance testing protocols

- Maintain clear communication channels between all stakeholders

Conclusion: Success Through Systematic Approach

While roof assembly failures cannot be considered successful outcomes, the systematic identification and resolution process demonstrates building envelope commissioning value. Without proper BECx implementation, these deficiencies would likely have manifested as catastrophic failures in an operational data center environment.

The project illustrates that comprehensive building envelope commissioning, despite implementation challenges, provides essential protection for mission-critical facilities. The lessons learned emphasize the importance of early integration, systematic quality assurance, and collaborative problem-solving in delivering high-performance building envelopes for data center applications.

For facility owners and construction professionals, this case study reinforces that investing in proper building envelope commissioning protocols pays dividends in avoiding costly post-occupancy failures and ensuring long-term asset protection in critical facility environments.

“Integrate Building Envelope Commissioning plan into the Design, Pre-Construction, and Construction phases. Though not code required, it should be recommended to Owners as part of the Owner Project Requirements to ensure that the shell, the protective barrier separating interior and exterior environments, is designed and constructed for longevity and resilience."

SOCOTEC Brochure : Data Centers

WEBINAR - Building Envelope Commissioning for Data Centers: Preventing Costly Failures Through Quality Assurance

Join SOCOTEC's building envelope experts for an essential presentation on safeguarding data center investments through comprehensive Building Envelope Commissioning.

November 4th, 2025

12PM PT | 2PM CT | 3PM ET

Ready to Discuss You Next Data Center Project and Protect Your Critical Infrastructure Investment?

Speak with one of our data centers experts to explore solutions, coordination strategies, and best practices for data centers and mission-critical facilities.

You may also like

Get the latest updates about SOCOTEC, subscribe to our newsletter!

Get the latest updates about SOCOTEC, subscribe to our newsletter!